Our Engineering

RF System and Component Design

The development and design of RF systems and components for satcom applications is MIRADs well known key competence. Our clients rely on us to meet their particular and individual system specifications with our tailor-made high performance solutions. It requires in-depth experience in RF and manufacturing technologies as well as system understanding for satellite communications. Depending on frequency and antenna size, the space for tracking system, polarization selection and mode conversion is often limited. This leads complex and compact systems and component designs which requires interdisciplinary engineering and technical skills. Our team has access to the latest simulation tools for computer aided engineering such as µWave Wizard from Mician or CST Studio Suite. In combination with mechanical design and simulation tools, we can perform multiphysics analysis of RF devices and systems. Especially in the field of RF power transmission, suitable cooling concepts with forced air or water cooling are required to ensure an appropriate system design.

Through continuous know-how transfer and further expansion, MIRAD has built up a high level of knowledge and experience in various technical disciplines over the past 30 years.

Antenna Design and Analysis

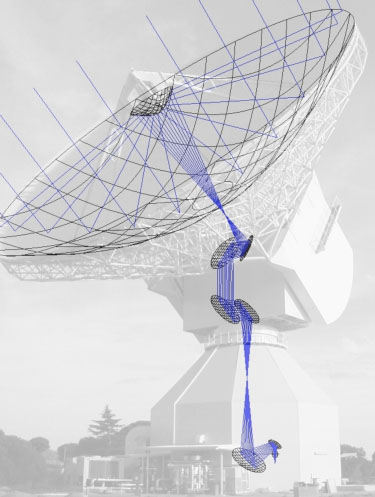

Another playground where MIRAD can use its advantages of precise and adequate development competence is antenna design. MIRAD’s spectrum ranges from reflector shaping of small aperture antennas to standard double reflector antennas to complex beam waveguide (BWG) systems as used for deep space communication. With latest state-of-the art design tools for reflector systems, we provide accurate analysis and an overall design optimization. For the primary radiator (feed horn), we can either use existing data delivered by our customer or we provide a fundamentally new and own design that fully covers the needs and requirements and results in best possible system performance. Our engineering service has its special focus on:

- Antenna geometries for the main- and sub-reflector design for new ground stations including reflector deformation analysis

- Antenna performance simulations (efficiency, radiation pattern, G/T calculations)

- Definition of the key parameters of existing antennas as a starting point for the feed system design

- Feasibility assessment of antenna upgrades (change or expansion of frequency bands)

- Beam waveguide design for large ground stations

Manufacturing & Assembly

Thanks to today’s powerful simulation and design software, prototyping has become almost obsolete. For process engineering, however, it is still necessary to manufacture certain parts for test purposes or to validate new designs. Especially at high frequency levels above Ka-band the parts require very high manufacturing precision. For this purpose, MIRAD has its own prototype laboratory equipped with the latest numerically controlled computer (CNC) technology and conventional machines operated by highly skilled mechanics.

The laboratory is used for research processes, for the production of mearement equipment or for small series when the delivery time is critical for our customers. The resulting conclusions are an excellent input for our engineering team and ensure high quality products. In addition, MIRAD works closely with highly specialized suppliers who meet our high quality standards. All components and products are inspected, assembled and finished by our qualified manufacturing team.

Measurement and Verification

MIRAD benefits from an up-to-date measurement infrastructure for testing the electrical and mechanical behavior of the developed systems and components. Our measurement equipment covers frequency ranges up to 70 GHz and is carefully maintained and regularly upgraded. The heart of our test infrastructure is the anechoic chamber (8m x 6m x 6m), which provides the capacity to test antennas and feed systems from L-band up to V-band. The radiation pattern can be measured and analyzed in three dimensions with very high resolution.

In addition to our four vector network analyzers, MIRAD has several HPAs, LNAs, power meters and other relevant measurement equipment in its facility. This allows us to validate passive intermodulation products (PIM) in the frequency range of 6 to 18GHz.

In addition, MIRAD performs mechanical testing and measurements, such as airtightness and pressure testing as well as mechanical accuracy verification through our own mechanical testing infrastructure.